HYTORC is a forerunner in terms of hydraulic wrenches but these tools do not meet all the needs of industrialists and professionals so HYTORC has developed its own range of torque wrenches to address this part of the market by bringing its expertise and maintaining the quality of its tools. A torque screwdriver does not require a hydraulic unit and guarantees the precision of the applied torque, unlike the impact screwdrivers widely used a few years ago for these purposes.

These pneumatic bolters, appreciated for their speed and ease of use, had a too approximate precision, so the industrial screwdrivers with torque control are necessary as soon as the work requires precision. HYTORC started in this market with the pneumatic torque screwdrivers of the JGUN series in 2006 and completed its offer with the battery electric torque screwdrivers since 2015.

The most popular Industrial Screwdriver is a battery screwdriver that offers power to the operator and the best possible autonomy in his work. The operator no longer has to worry about the energy available on his work site, nor about having to deal with power cables or hoses that could hinder his handling of the screwdriver. HYTORC has developed two ranges of battery-powered torque screwdrivers, 18V and 36V, to suit the needs and intensity of use. These Li-Ion battery screwdrivers offer long autonomy and come with two batteries, so there’s no break in work, as the second battery has plenty of time to charge before the one powering the cordless torque screwdriver is discharged.

.

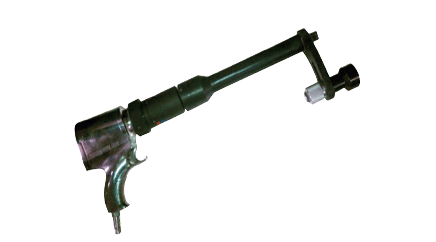

Pneumatic screwdrivers are the most widely used pneumatic tools on building sites for torques that are difficult to make with manual wrenches. Pneumatic screwdrivers do not provide acceptable accuracy for some applications, or are no longer accepted because of the vibration levels transmitted to the operator. Using a dynamometric pneumatic screwdriver, such as the JGUN DUAL SPEED allows you to achieve precise and, above all, powerful tightening of up to 10,000 N.m with a simple on-site compressor or your own compressed air network. Torque tightening requires a fixed, solid reaction point to develop the force, so all screwdrivers are supplied with a reaction arm.

.

HYTORC torque screwdrivers feature a motor whether pneumatic or electric combined with an epicyclic gear train that acts as an integrated torque multiplier. This makes it possible to have a professional screwdriver unscrewer with smooth, progressive application of torque, however large.