HYTORC started with the manufacture of hydraulic wrenches based on a hydraulic cylinder. When you say cylinder, you say hydraulic pump to feed it and it is quite naturally that HYTORC had to integrate these products in its range. For a long time reseller of pumps manufactured according to its own specifications, HYTORC bought in 2015 a specialized German factory to allow to innovate in depth to get the best out of the key / hydraulic pump binomial.

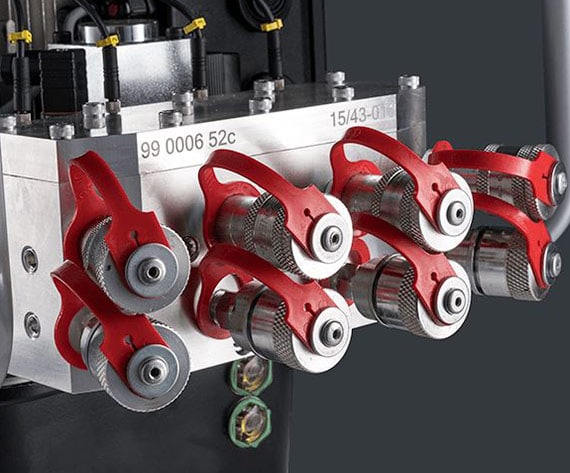

HYTORC hydraulic wrenches are all double acting 700 bar so it is obvious that all HYTORC hydraulic pumps are also double acting 700 bar. In addition to the traditional pumps with manual push/return/stop controls, the range now includes pumps with automatic cycles, database and clamping operation recording.

Power supply is the easiest source to find in a workshop especially since HYTORC hydraulic pumps work very well with 230 V 50 Hz available everywhere. All specifications given are for a 230 V 50 Hz supply. The various versions deliver a good 700 bar to enable you to get the maximum torque from each hydraulic wrench.

HYTORC used with and they differ in the flow rate they can deliver. The nominal flow rate mentioned corresponds to the quantity of oil circulating at a pressure of 70 bar. During a clamping operation, only the last cycles require torque and therefore pressure to finish the clamping, and a cycle is made up of a thrust phase through the High Pressure circuit and a piston return phase at low pressure.

The flow rate at 70 bar is a representative criterion for comparing pump speeds. When using very large wrenches, models 35 and above, or several large wrenches in SIMULTORC mode, higher flow rates may be justified on critical operations, and larger pumps exist with 380 V motors to maximize performance. Note that the JETPRO 9.3 hydraulic pump and VECTOR hydraulic pump models feature oil coolers for intensive use in production or heavy maintenance operations.

.

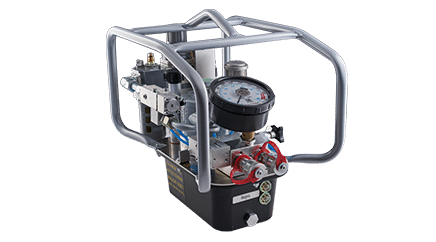

On outdoor worksites and in ATEX zones, pneumatic power is preferable, and there’s a range of air-motor hydraulic pumps offering the same performance as electric versions. A simple worksite compressor supplies the compressed air needed by the motor to power any hydraulic wrench up to 700 bar. For intensive use, the HY AIR hydraulic pump is equipped with an INTERCOOLER cooling system, which consists of circulating the expanded air leaving the motor in a metal tube down into the reservoir in contact with the oil, before exiting through the exhaust.

At the same time, the HY AIR hydraulic pump is equipped with an INTERCOOLER cooling system.

As the expanded air is extremely cold, it keeps the oil at a reasonable temperature even when used at high pressure or in extreme heat. The air motor pumps feature an integrated FRL (Filter Regulator Lubricator) unit that treats the compressed air to keep the air motor in good working order. The pneumatic remote control is as simple to use as an electric one, for easy control of clamping operations.