The HYTORC clamping method at the elastic limit is an optimal industrial clamping technique.

The preload forces applied to the bolts are often undersized so that they do not exceed the yield point when tightened by torque or tensioner.

The common denominator of the connections is that one wishes to remain in the elastic range of the bolt to control its behavior and guarantee the connection.

The problem that arises is that depending on the precision of the tool used and the tightening conditions, there is always a safety margin that is taken to avoid crossing the elastic limit.

Tightening with a system that detects the elastic limit to stop the tightening is safe because it allows you to make the most of your bolts without the risk of unexpected mechanical damage.

The assurance of tightening bolts to the elastic limit ensures that the bolt and assembly plate or flange size is exactly appropriate for the force required for a good hold.

This translates into significant space, weight and cost savings on assembly design.

Bolts are chosen in relation to the pressure force they can exert on an assembly to ensure it is held securely over the course of the device’s use or the machine’s life.

A large-diameter bolt can exert a greater force on a bolted assembly than a bolt with a smaller cross-section.

Similarly, some materials enable greater tension to be applied without changing diameter. With conventional means of tightening, the safety margin retained leads to all bolts being oversized, only to be used at 80 or 90% of their maximum capacity without any further mechanical justification.

The [[L-0-0]] bolt is a bolt with a larger cross-sectional area than a bolt with a smaller cross-sectional area.

The hydraulic pump data logger shows the final torque achieved, and by comparing the values obtained from one bolt to another, it is possible to detect problems of material quality (steel, stainless steel, etc.), lubrication or other defects…

The idea is to stop the tightening of the bolt when there is an inflection in the ratio between torque evolution and tool rotation angle evolution.

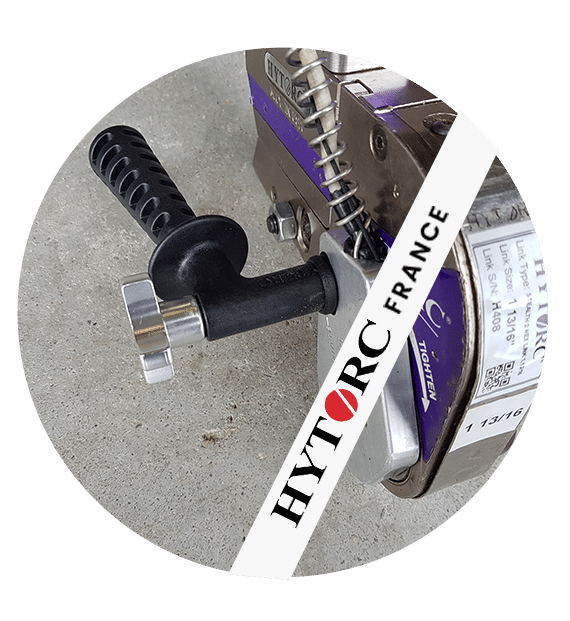

It is therefore necessary to equip the hydraulic wrench with an angle sensor that will be able to give this additional information to the pump.

The hydraulic pump controls tightening by measuring in real time and simultaneously the pressure information sent to the hydraulic wrench (synonymous with the torque value applied to the bolt) and resulting angle of rotation.

The ratio is constant in the elastic domain because the angle reflects the elongation of the screw or threaded rod, which is proportional to the tension force.

As soon as the pump electronics detect a variation in the ratio meaning that less torque is needed for the same angle, it stops and tightening is completed on the elastic limit.