HYTORC has developed a wide range of torque tightening tools equipped to meet the most common cases in accordance with the bolted connections standards in force and their evolutions.

If these tools are sufficient on their own for simple cases such as standardized sealing flanges, the situation is different for special machines and assemblies of metal structures.

Depending on the case, it is necessary to provide tightening accessories to be able to carry out the assembly operations while preserving the safety of the operators and the integrity of the devices in order to be able to deliver a dynamometric torque despite everything.

Aside from hydraulic eye wrenches, all other tools require a bushing to interface between tool and bolt. This bushing is a critical link in the application of torque, ensuring the transmission of a very high torque effort, and must therefore have very high strength. HYTORC supplies impact-quality sockets usually used with impact wrenches, to guarantee greater safety for operators. All sockets, whether male or female, guarantee successful work under the best possible conditions.

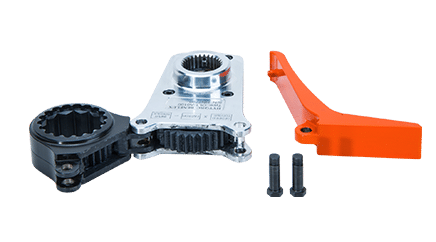

If the height does not allow the use of a socket, there are Offset Links HYTORC cartridges which, mounted on the tool’s square drive, allow the bolt to be tightened to torque with a footprint reduced to a minimum.

.

Contrary to the impact wrenches known to all, to apply torque with precision, HYTORC torque tools work without vibration but with support. To achieve this, the tightening tool, whether a hydraulic wrench or a torque screwdriver, has to be supported by a fixed, solid point that will enable it to develop the precise torque required. Unfortunately, in some cases it is difficult to reach a reaction point for reasons of distance or resistance. A suitable arm must therefore be provided, and HYTORC has already designed a wide variety of solutions for all its tools, thanks to some fifty years’ experience.

.

Torque tightening can lead to complete rotation of the bolt being tightened. To remedy this common phenomenon, the opposite nut must be retained, and HYTORC therefore offers two different methods. The optimum method is to replace the flat washers under the opposite nut with a HYTORC backup washer, which directly cancels out the problem without the need for tools or a dedicated operator. And the conventional method by providing counter keys that will prevent rotation either purely mechanically or with hydraulic assistance for greater ease.

.

Once the tool has been configured to develop the torque required to tighten or loosen the bolt, it may be that the tightening zone is far from where the hydraulic pump that will supply the pressure can be positioned. Or when the bolt is high up and the pump has to remain on the ground or on a more suitable platform below. In this case, the hoses cannot be assembled end-to-end, as they would cause the hydraulic circuit to reverse and disrupt the normal operation of the hydraulic wrench. It is therefore imperative to choose hoses of a length suited to its operation.

.

HYTORC twin hoses are also certified with a 4:1 safety coefficient on burst pressure to prevent accidents, and their structure ensures good protection against the risks inherent in site conditions.

.

Depending on the regulations in force in your company with regard to hydraulic tools, Push Pull quick couplings, for example, can be fitted to meet the required criteria without altering operation.

.